- +86 13869171699

- greentech@vip.163.com

Core Application Areas

1. Wastewater Treatment and Municipal Environmental Protection

Application Point: Aeration and oxygen supply (activated sludge process).

Advantages:

High Efficiency and Energy Savings: Utilizes high-speed variable frequency motors and air foil bearings, offering extremely high efficiency at partial loads, resulting in 20%-35% energy savings compared to traditional Roots blowers.

Precise Control: Can adjust air flow in real-time based on dissolved oxygen (DO) signals, enabling process optimization.

Oil-Free and Eco-Friendly: 100% oil-free, eliminating any risk of water contamination.

Easy Installation: Compact design requires no complex foundations or large piping, saving space.

2. Food, Beverage, Bioprocessing, and Pharmaceutical Industries

Application Points: Fermentation tank aeration, process gas delivery, clean air supply, pneumatic conveying of materials.

Advantages:

Absolute Purity: No lubricating oil ensures compressed air meets stringent food and pharmaceutical hygiene and safety standards such as GMP, FDA, and HACCP.

Stable and Controlled Operation: Delivers stable, precisely controllable pressure and flow, creating the optimal environment for sensitive fermentation processes.

Low Maintenance: Reduces cleaning and maintenance downtime caused by oil contamination.

3. Textile and Chemical Fiber Industry

Application Points: Air-jet spinning, air-jet looms, fiber drying and conveying.

Advantages:

High-Quality Air Supply: Provides stable, dry, and oil-free air, completely preventing oil stains on high-grade fabrics and improving product yield.

Energy Savings and Cost Reduction: The significant air consumption of air-jet looms makes the variable frequency energy-saving feature of air foil blowers highly effective in lowering production costs.

4. Pneumatic Conveying Systems

Application Points: Conveying bulk materials such as cement, fly ash, grains, plastic pellets, and chemical powders.

Advantages:

Adjustable Flow Rate: Variable frequency drive easily adapts to different conveying distances and material load variations.

Stable Operation: Provides consistent and stable pressure, ensuring uninterrupted material flow and preventing pipeline blockages.

Material Purity: Oil-free air prevents contamination of sensitive materials.

5. Aquaculture

Application Points: Aeration and air blowing for Recirculating Aquaculture Systems (RAS) and deep-water cage culture.

Advantages:

Direct Energy Savings: Operating electricity is a major cost; high efficiency directly enhances farming economic benefits.

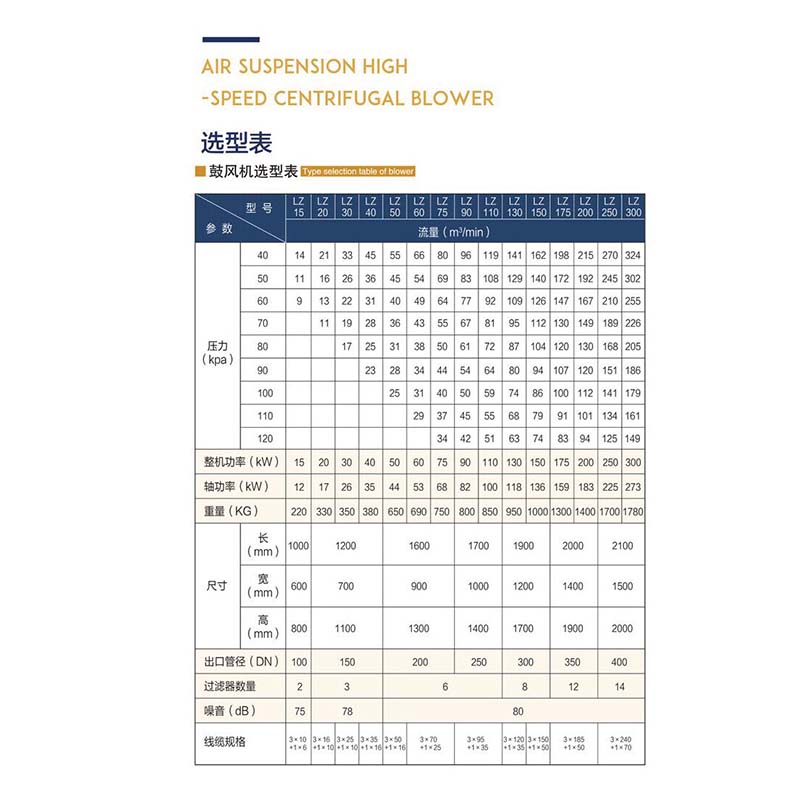

Quiet Operation: Low noise levels (typically below 80 dB) reduce stress on aquatic life.

Remote Control: Facilitates centralized and intelligent management for large-scale farms.

6. Other Industrial and Specialized Fields

Printing and Packaging: Provides a clean air source for pneumatic components and paper feeding devices.

Electronics Manufacturing: PCB board cleaning and drying processes.

Pilot-scale Laboratories: Requires a clean air source with low flow, high pressure, and precise adjustability.

English ▼

English ▼